In this post, we cover multiple topics to help supplement the information we have discussed already.

Light Reflection

Light reflectors and reflective surfaces can play an important role in how light is distributed across your growing space and how light intensity changes based on crop location relative to the light and reflective surfaces (e.g., walls).

Let’s explore this by taking a look at four different theoretical light reflector setups and see how they distribute light:

Single light no reflector

- This setup distributes light well across two trays of a tall crop, with just the outside edges losing direct light.

- Edges of crops may stretch or lean towards the light which can lower crop quality

Single light, reflector

- The ends of this tall crop are growing well outside of direct light

- This setup (though common), results in inconsistent crop quality

Two lights, no reflector

- This setup concentrates light in the middle while still reaching the crop edges

- This is an effective light distribution set up, but there could be wasted light on the sides for shorter crops.

Two lights, reflectors

- This setup helps concentrate the light, with the crop just barely reaching above in parts.

- For taller crops, they could grow outside of the line of direct light, but should provide coverage in most cases

Wall and Barrier Reflection

Reflectors on lights can help concentrate light into your growing space. To complement this, wall and barrier reflection can help reduce light from “escaping” your grow space.

In our research space, our shelves are up against a highly reflective white wall. We find this results in PPFD values being 15 to 20% higher in the back of the shelf than in the front in all our measurements.

We have also had success using white reflective surfaces on the sides of the shelf to redirect even more light back to the growing space.

We have noticed many growers will undermine the value of reflectivity in making the best use of lights, but 20% more light can go a long way in improving crop quality and light efficiency.

Lighting Efficiency and Degradation

Light Efficiency

Lighting efficiency refers to how much PAR you get per unit of energy used, measured in µmol/joule or µmol/W or µmol/kWh. The higher the value, the more photons you get per Watt of power used. This is an important measure that is often overlooked.

In one of our lighting measurement exercises, we measured the following PAR values from a number of light sources:

| Light Unit | Total Watts | Average PPFD(μmol/m2s) | PPFD/W Average(μmol/m2s/W) |

| Light 1 no reflectors x 2 | 84 | 110.7 | 1.3 |

| Light 1 w/reflectors x 2 | 84 | 93.3 | 1.1 |

| Light 2 no reflectors x 2 | 84 | 141.0 | 1.7 |

| Light 2 w/reflectors x 2 | 84 | 74.0 | 0.9 |

| Light 3 x 2 | 40 | 90.7 | 2.3 |

| Light 4 x 2 | 62 | 165.7 | 2.7 |

From the table we can see that there is a lot of variation in lighting efficiency. For example, “Light 4” provides three times the amount of light per Watt than “Light 2 w/reflectors”. More efficient lights mean you will use less energy to get the amount of light you want.

This is an often overlooked aspect of lighting. Lights 1 and 2 are the popular Barrina lights frequently used by microgreens growers, which often have good light quality, but lack efficiency.

Light Degradation

As your lighting fixtures age, the quality and efficiency of your light tends to decrease. Here are some things you can do to monitor and prevent the loss of lighting quality:

- Take regular PAR measurements so you can document the change in light

- Check for defective LEDs in LED fixtures

- Keep your fixtures clean – some light loss may be due to dust or debris build up on the lights themselves

Light Proximity to Crop

The distance you set your lights from your crop will depend on your desired PPFD and DLI values. You need to leave enough room between the two to ensure the crop does not attempt to grow right into your lights. Further, as your crop gets taller, its relation to your lights can change light quality in different ways – improving it in some spots but lowering quality in others – this will depend greatly on your mature crop height and your lighting configuration.

A good starting point is to set the lights about 10” to 12” or 25 cm to 30 cm from the soil surface of the crop you are growing. Measure your PPFD value at that point. Now consider, the crop will not be exposed to the light until it is about one inch or 2.5 cm tall – so also measure your PPFD value at that point.

Understanding PPFD and DLI values in lighting is important when setting up your system – especially if you have some natural light in your system, which will always be variable. Using lower wattage lights will usually give lower PPFD values and can allow you to set your lights close to your crops. Closer crop-light spacing may allow you to better utilize vertical space to maximize your growing space’s output.

Also keep in mind that LED lights do give off some heat, so as the crop gets closer to the light the growing conditions can change. More heat can speed up growth and crop transpiration and change your watering needs. Further, the crop closest to the light can block the light from reaching the rest of the crop.

Light spacing is a function of shelf spacing and light placement on those shelves. Ideally, we want to have our shelves as close together as possible for two reasons:

The closer you can space your shelves, the more shelves you can fit in an area to make best use of your vertical space. Further, the closer your crop is to the lights, without being too close, the higher the PPFD you can achieve with lower energy use – which will keep your energy costs down.

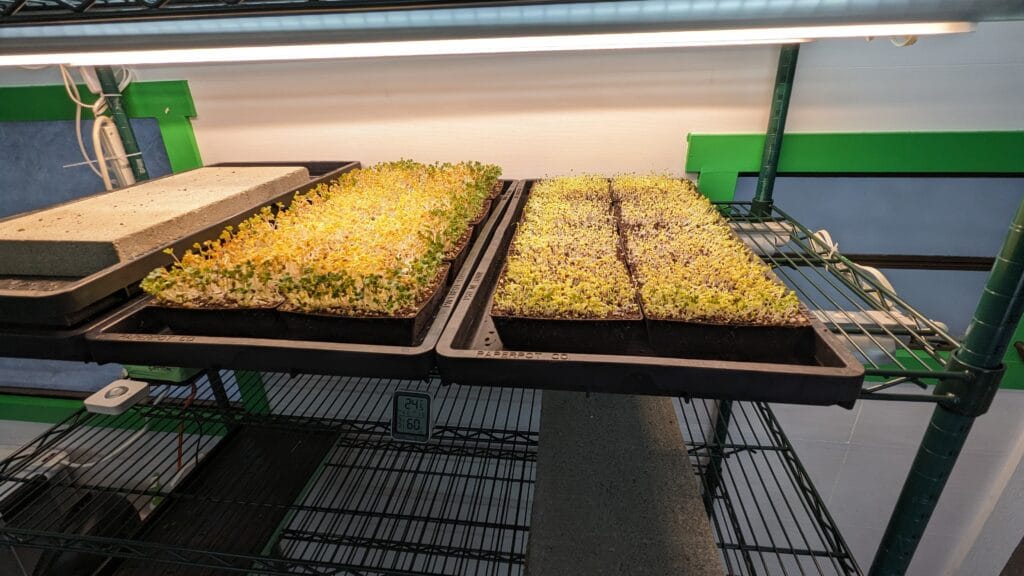

In the image to the right, shelves are spaced at 12 inches (30 cm) and the lights nest under the top shelf giving a distance of 9 inches or 23 cm from the light to the top of the crop at uncovering time. PPFD at 23 cm is about 110 µmol/m2s.

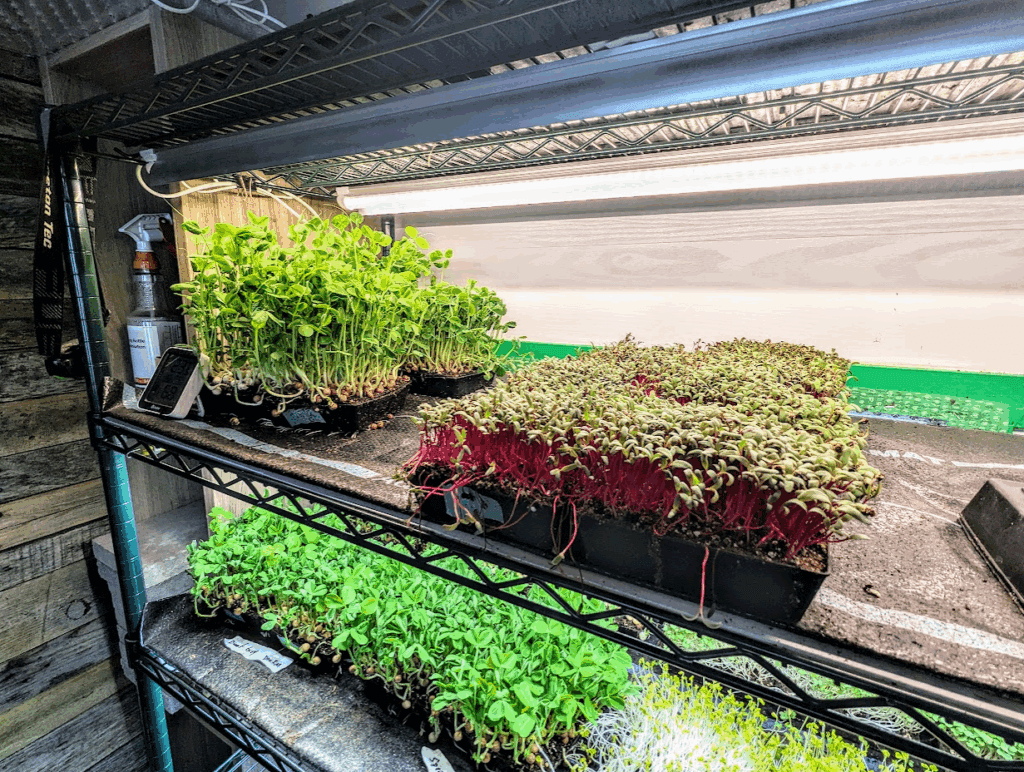

This shelf spacing accommodates both tall and short crops (see image below). If only short crops were being grown, we could move the shelf 2 to 3 inches (5 to 8 cm) closer to increase PPFD to 140 or 150 µmol/m2s.

Shelf spacing overall contributes to three things:

- How many shelves we can stack in a vertical space

- How tall of a crop we can grow on a given shelf

- How close the crop is to the light and thus influencing light PPFD values

In most cases we want the shelves to be as close together as possible to make best use of space. If you are growing a mix of tall and short crops, you may have varying shelf spacing to accommodate both types of crops at their optimum spacing. Because shelf spacing affects PPFD, it is important to correspond shelf spacing with your lighting choice, which could take some trial and error.

Leave a Reply