Garage-Based Microgreens Production: A Practical Intermediate Step

Introduction

If you’ve outgrown your living room grow rack but aren’t quite ready for a commercial lease, a garage can be the perfect transitional space. Garages offer more flexibility and capacity than indoor home setups, while still benefiting from the cost-saving advantages of using property you already own or rent. Many successful growers scale up to a garage setup before making the leap into a warehouse or greenhouse.

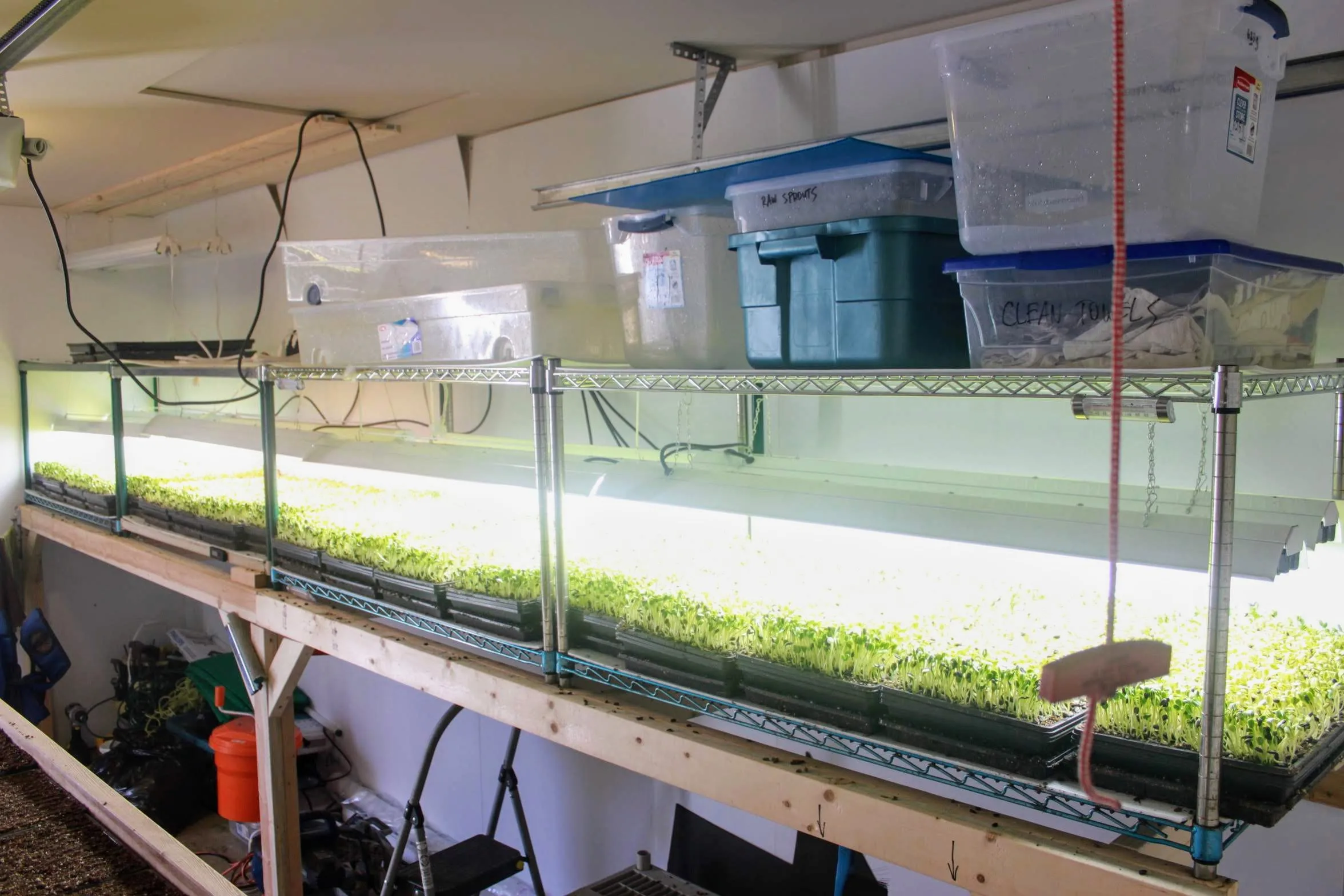

Garages provide a dedicated space that can be better controlled and separated from your daily living area. This separation is critical when you’re harvesting trays, dealing with soil, or managing cleaning and sanitizing. You can install multiple shelving units, set up fans for airflow, and even section off different zones for germination, growing, and harvesting. With a bit of planning, it’s possible to build a compact, efficient mini-farm in a single or double-car garage.

Setting up Your Garage to Grow Microgreens

In terms of infrastructure, garages can usually be modified to meet most microgreens production needs. While water access and drainage can be a challenge — especially in attached garages — these issues can often be resolved with minimal plumbing work, portable water tanks, or temporary gray water collection systems. Lighting setups are similar to home systems: shelves with fluorescent or LED grow lights, spaced to allow optimal light exposure and airflow.

Humidity and temperature control are two of the biggest challenges in garage growing. Garages are often uninsulated and unheated, making them vulnerable to seasonal extremes. Adding a small electric heater, exhaust fans, and dehumidifiers can go a long way in stabilizing the environment. Some growers even insulate or drywall their garage interiors to create a more consistent microclimate.

Regulatory concerns are less stringent in a garage than inside your main home, but they still apply. If you’re selling commercially, you’ll need to ensure the space meets local food safety standards. Having a cleanable surface (e.g., sealed concrete or vinyl flooring), good airflow, and a pest-proof environment is essential. You’ll also need to be mindful of electrical load — multiple grow lights and fans can draw a lot of power, so it’s wise to inspect your circuits and outlets.

In Closing

While garages still present some limitations, they are a clear step up in scale and professionalism from in-home setups. They provide more flexibility, better separation of tasks, and are often sufficient for growers producing 50–150 trays per week. Best of all, they allow you to build revenue and refine your systems before committing to a larger, more permanent space.

Leave a Reply